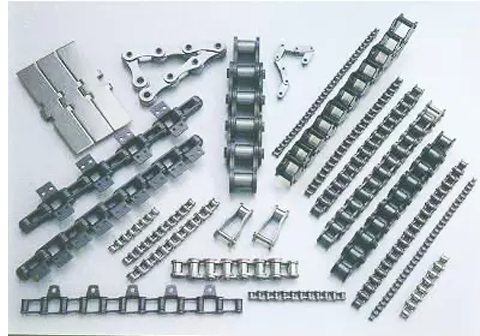

Mill Chains

We focus on all kinds of mechanical products, looking forward to your purchase

LEARN MORE

Mill Chains is an extremely strong, serviceable chain originally designed for heavy drives and transfer conveyor purposes in saw mills and the paper and pulp industry.

Chain has proven itself for innumerable other industrial applications as well, especially for moderate duty in abrasive atmospheres where heavy, rugged chain is required. The sidebars of the links are reinforced with wearing shoes which strengthen and stiffen the links when it is operated in troughs or over floors and runways. Pin holes are precision cored to assure accurate pitch sizes, which range from 2.308 to 4.000 inches. Chain is available in both riveted and cottered construction. T-head pins engage two lugs cast on the links’ sidebars. This configuration prohibits pin rotation during chain operation, eliminating abrasive wear and pitch elongation.

Chain conforms to manufacturer’s standards and is completely interchangeable with chains of other manufacturers. Chain is available in Promal (Duramal) with tensile ranges of 9,450 to 40,500 pounds.

Chain may operate in two directions. As a drive chain, it travels in the direction of the closed barrel; for elevator or conveyor applications, it should travel toward the open ends of the links.

Brutaloy or cast steel sprockets are available to accommodate every

pitch size. A wide assortment of attachments is also available for varied chain applications.

SUGAR MILL CHAIN

China Chain manufacturer & exporter, we specialize in: Transmission chain(Driving Chain), Conveyor Chain, Engineering Chain, Stainless Steel Chain, Lifting Chain, Agricultural Chain, Forging Series, Cast Iron Chain.

Features

Features

①Top-performing square-corner chisel cutters.

②Hard industrial plated cutter provider superior corrosion resistance.

③US-imported SAE8660 steel provides greater durability, especially in cold cutting conditions.Long life, not easy to jam, low noise

Other Products

planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vaccum pumps, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings.

Main Products

We have many types mill chain for you to choose

Roller Conveyor Chain

1. Chain types: Roller Chain, conveyor chain, transmission chain, motorcycle roller chain, silent chains, oil pump chains, weld steel drag chains, plastic chains etc;

2. Main materials: It is 40Mn. 40Cr, 45Mn alloy steel, SUS304, and POM Plastic for plates, 10#, 20#, 20CrMnMo, 30CrMnTi for pins and rollers;

Carrier Sugar Mill Roller Conveyor Chain for Transmission

steel with high quality after heat-treatment are used for

sugar mill chains to ensure hingh wear-resistance

The offset link chain is designed with high abrasion, impact, and corrosion resistance to meet the application demands in sugar making industry. Its side plates are bended but with paralleled ends. Both hot bending and cold bending methods can be applied for side plate processing.

The adoption of advanced bending die, coupled with enhanced quality inspection, makes sure the bending of side plates comes without cracks. Therefore, the offset sidebar chain won’t break easily under heavy load conditions.

Made using stainless steel and alloy steel materials, our offset link chain for sugar industry offers minimum tensile strength options between 250 and 900KN, and rated working load options from18 to 85KN.